Is your company prepared to handle OSHA’s new silica standard?

Many businesses struggle to stay in compliance with existing OSHA standards and regulations. This goes double for any business without a dedicated safety professional on staff. And it’s even worse when a new standard or regulation comes into effect.

OSHA standards and regulations are hard to navigate for the inexperienced, but are necessary to eventually understand and be in compliance with to stay out of trouble with OSHA, and keeping your staff safe while on the job.

One such issue we’re hearing about left and right is businesses attempting to stay in compliance with the new OSHA standard on silica. This new standard is quickly becoming a hot button issue for many businesses out there, so let’s take a dive into what the new OSHA silica standard means for businesses.

What does the OSHA’s Crystalline Silica Rule mean for your organization?

Crystalline silica is a very common mineral found in the earth’s crust. Naturally occurring materials such as sand, soil, and stone contain silica, meaning materials we create such as crushed aggregates, concrete, mortar, glass, pottery, ceramics, bricks, and artificial stone also contain crystalline silica.

In short, the mineral is extremely common in a variety of materials found at a variety of businesses in both the construction industries, general industries, and maritime industries.

Why did OSHA develop the Crystalline Silica Rule?

One word: respiration.

Crystalline silica is small. Very small. In fact, crystalline silica is over 100 times smaller than the sand you might find on beaches and playgrounds.

To better protect workers exposed to respirable crystalline silica, OSHA has issued two new respirable crystalline silica standards: one for construction and the other for general industry and maritime. Various parts of OSHA’s Crystalline Silica Rule have been effect since the summer, but OSHA will begin enforcing most provisions of the standard for construction on September 23, 2017.

What are the impacts of silica on the staff at my business?

As stated, respiration of crystalline silica is the issue here. Just like any other substance that is inhaled, these foreign objects increase the risk of developing serious silica-related diseases, such as:

- Silicosis, an incurable lung disease that can lead to disability and death

- Lung cancer

- Chronic obstructive pulmonary disease (COPD)

- Kidney disease

In short, silica can be an extremely dangerous material if inhaled, which is why OSHA has created the Respirable Crystalline Silica standards.

Where does crystalline silica come from?

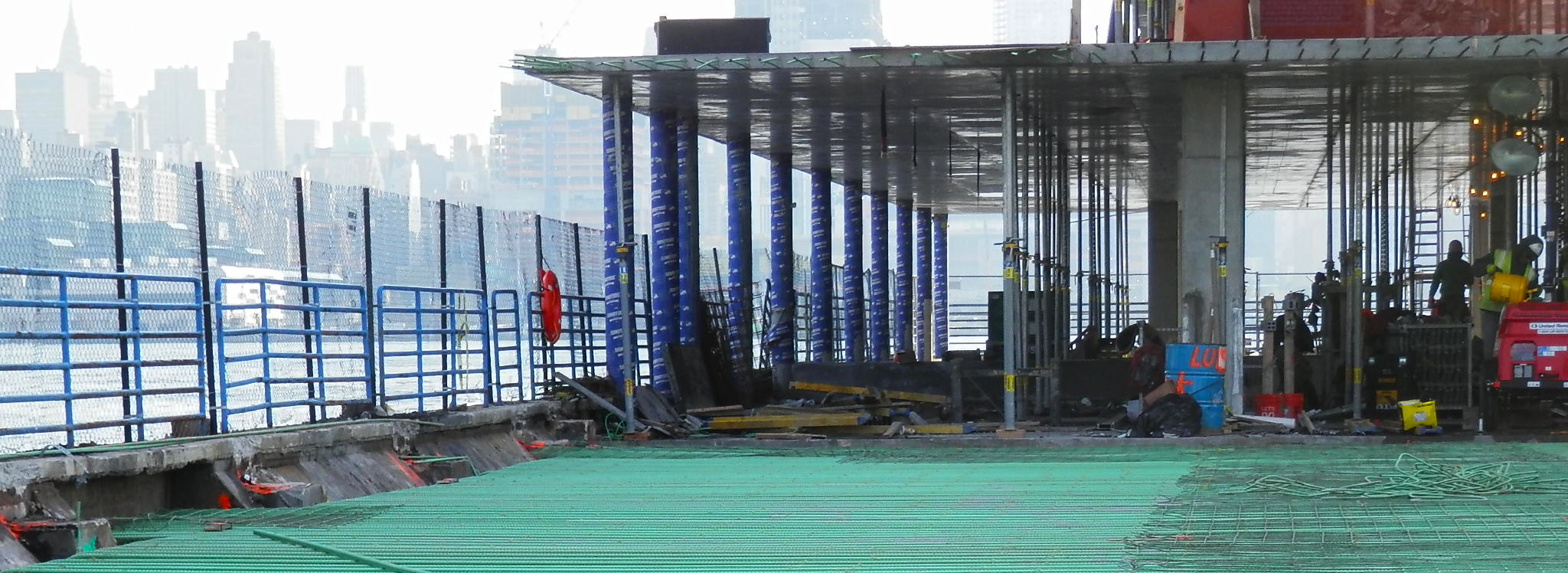

This extremely fine material is turned into a breathable material from cutting, sawing, grinding, drilling, sanding, and crushing stone, rock, concrete, brick, block, spackle, and mortar.

Here’s a few common ways silica can be generated:

- Abrasive blasting with sand.

- Sawing brick or concrete.

- Sanding or drilling into concrete walls.

- Grinding mortar.

- Sanding spackle.

- Manufacturing brick, concrete blocks, stone countertops, or ceramic products.

- Cutting or crushing stone.

All of these activities, as well as many more, can result in your staff members being exposed to respirable crystalline silica dust. In fact, it’s estimated that about 2.3 million people in the United State are exposed to silica while at work.

In short, it’s a big issue impacting millions which is why OSHA’s Crystalline Silica Rule was created in the first place.

How can my business get in compliance with OSHA’s Respirable Crystalline Silica standards?

There’s two fact sheets OSHA’s put out regarding the new Respirable Crystalline Silica standards.

- OSHA’s Crystalline Silica Rule: General Industry and Maritime

- OSHA’s Crystalline Silica Rule: Construction

These two fact sheets go over some of the new things to be concerned about regarding the new standards, but here’s some quick info as we see it.

OSHA’s Crystalline Silica Rule: Construction

The new silica standard for construction requires employers to limit worker exposure to respirable crystalline silica and to take other steps to protect workers.

The standard provides flexible alternatives, which OSHA expects will be especially useful for small employers. Employers can either use various, specific control methods or they can measure workers’ exposure to silica and independently decide which dust controls work best to limit exposures to the PEL in their workplaces.

Regardless of which exposure control method is used, all construction employers covered by the standard are required to:

- Establish and implement a written Silica control plan that identifies tasks that involve exposure and methods used to protect workers, including procedures to restrict access to work areas where high exposures may occur.

- Designate a competent person to implement the written Silica control plan.

- Restrict housekeeping practices that expose workers to silica where feasible alternatives are available.

- Offer medical exams-including chest X-rays and lung function tests-every three years for workers who are required by the standard to wear a respirator for 30 or more days per year.

- Train workers on work operations that result in silica exposure and ways to limit exposure.

- Keep records of exposure measurements, objective data, and medical exams.

- Additional provisions may apply such as; HazCom training, CIH Silica air testing services, respiratory fit testing & training, and written safety programs.

Construction employers must comply with all requirements of the standard by September 23, 2017, full OSHA enforcement of the standard is expected to take place on October 23, 2017.

OSHA’s Crystalline Silica Rule: General Industry and Maritime

Just like the construction industry, both general industry and maritime industries need to take steps to limit the exposure to respirable crystalline silica, including required actions such as:

- Measuring the amount of silica that workers are exposed to.

- Protecting workers from exposures above permissible limits, including limiting access to areas with potential silica exposure or providing respirators to workers.

- Use dust controls & restricting housekeeping practices that expose workers to silica where feasible alternatives are available.

- Offer medical exams-including chest X-rays and lung function tests-every three years for workers who are required by the standard to wear a respirator for 30 or more days per year.

- Train workers on work operations that result in silica exposure and ways to limit exposure.

- Keep records of exposure measurements, objective data, and medical exams.

What businesses will be impacted by OSHA’s new silica standard?

This is the million-dollar question, but I imagine if you’re reading this right now you’re already picturing the industries and businesses that are going to be impacted by OSHA’s Crystalline Silica Rule.

Here’s a couple of types of industries which will be impacted by the new OSHA silica standard the most:

- Masonry

- Precast & Ready-Mix Concrete Production

- Sheet Rockers

- Floor Finishers

- Demolition & Recycling

- Blacktop Milling & Roadwork

- Sandblasting

- Hardscaping

- Granite Finishers

- Facilities using industrial sand as part of operations, such as foundry work & hydraulic fracturing (fracking).

- Many, many more.

Where does your company stand with regards to OSHA’s new silica rule? To learn more about how Proactive Safety Solutions can help your business, click here to contact us or give us a call at 732-270-2900 to talk to one of our expert safety consultants.